Contact us

Contact us

We help you find the best product and solution

Contact us

Contact us

Not sure what you need?

Order free product samples and try them before making your decision.

All products

Can’t find what you’re looking for?

We are happy to guide you through our range and offer personalized recommendations for your project

support@tappex.se

News

The 16-18th of December we take inventory!

On December 16-18 we are closed for deliveries due to inventory.You can reach us as usual by phone and e-mail.

“Tappex’s cutting-edge expertise solves our customers’ challenges”

At Gamla Jernborden in Ronneby, both professionals and do-it-yourselfers can find a large part of Tappex’s product range. Everything from thread inserts and wire thread inserts to blind rivets and self clinch fasteners.

Merry Christmas!

From December 20th to January 7th, we will be closed for deliveries due to a business system upgrade. We wish you all a Merry Christmas and a Happy New Year!

News

The 16-18th of December we take inventory!

On December 16-18 we are closed for deliveries due to inventory.You can reach us as usual by phone and e-mail.

“Tappex’s cutting-edge expertise solves our customers’ challenges”

At Gamla Jernborden in Ronneby, both professionals and do-it-yourselfers can find a large part of Tappex’s product range. Everything from thread inserts and wire thread inserts to blind rivets and self clinch fasteners.

Merry Christmas!

From December 20th to January 7th, we will be closed for deliveries due to a business system upgrade. We wish you all a Merry Christmas and a Happy New Year!

Suppliers

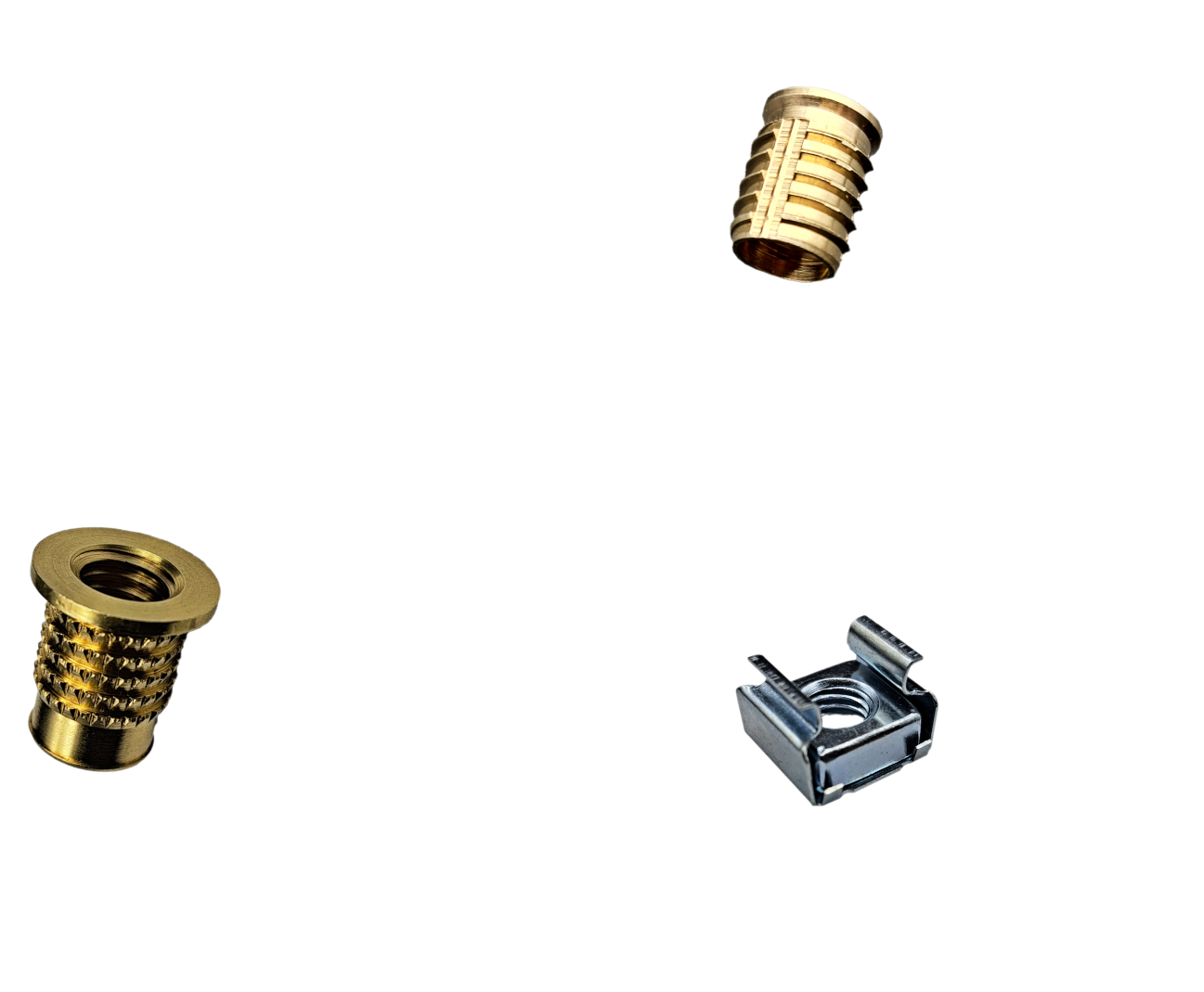

Our products

are used everywhere.

Frequently asked questions

What kind of blind rivet should I use?

There are many variants of blind rivets, made of different materials and with different functions. The rivet that suits best depends on several things, such as what it is being riveted together, whether the material is hard or soft, whether it is steel, stainless steel, aluminium or another material. Are there requirements regarding strength and, if so, what forces, tension or shear forces? What environment will the blind rivet be exposed to, does it come into contact with chemicals? Will the finished application be used indoors or outdoors? So, there are several things to consider when choosing blind rivets, but we have extensive experience of rivet joints so together with you, we’ll surely find a good solution.

The blind rivet nut is not attached; it rotates. Why?

Either the nut is incorrectly tightened, or the holes are wrong. Normally, the nut should not rotate if the part to be mounted has more than one attachment point. It’s important to choose the right material for the screw and blind rivet nut. In order to prevent rotation, it’s also important that what is screwed into place is flush with the top of the nut. To be absolutely sure – use a hexagonal nut.

It’s cramped on the back and the blind rivet nut gets too long. Is there a shorter one?

Yes. We have a blind rivet nut that we call CD Micro. It’s available in different variants that are shorter and are used where the space on the back side is limited, as in, for example, pipes.

What kind of thread insert is suitable for plastic?

It depends on what the plastic and the application look like. Will the thread insert be cast in or retrofitted? There are several things that determine what’s suitable. We have worked a lot with this type of thread insert and usually find a good solution that provides the joint the right performance and a viable assembly method. Contact us and we’ll find what suits you best.

The wire thread insert has been installed too deep. How do I get it out?

Here, it’s important not to destroy the surface or the entrance of the thread. This happens easily, especially on insert with a break tang. We often see cases where pliers were used to try to pull it out. With Tangless inserts, there is no tang to break, instead there is a track at both ends where a hook in the mounting tools should grip in and then drive the insert into the threaded hole. For disassembly, there is a similar tool where the hooh grips is in the other direction. The tool is turned counter-clockwise so that the insert is unscrewed, without damaging either the thread or the part.

The Self clinch nut isn’t fastened in the sheet metal, why?

The most common reason that the clinch nut does not fasten in the sheet metal is that the sheet is too hard. When a clinch nut is to be installed in sheet metal, it is therefore important that the nut is harder than the sheet metal in which it is to sit. If the sheet is softer than the nut, the material is pushed into all of the nut’s tracks and grooves and thereby keep it in place. Self clinch fasteners are available in several different materials, such as steel, stainless steel and aluminium. If nothing works and they still tend to detach from the sheet, a riveted fastener is an alternative. It has a spigot that goes through the sheet and is compressed down on the back so that you basically get a completely flush rivet joint.

Vacancies

There are no vacancies at the moment.

Sustainability

Traceability and quality

Reliable deliveries